incredibly easy rotovap design

12/31/2025

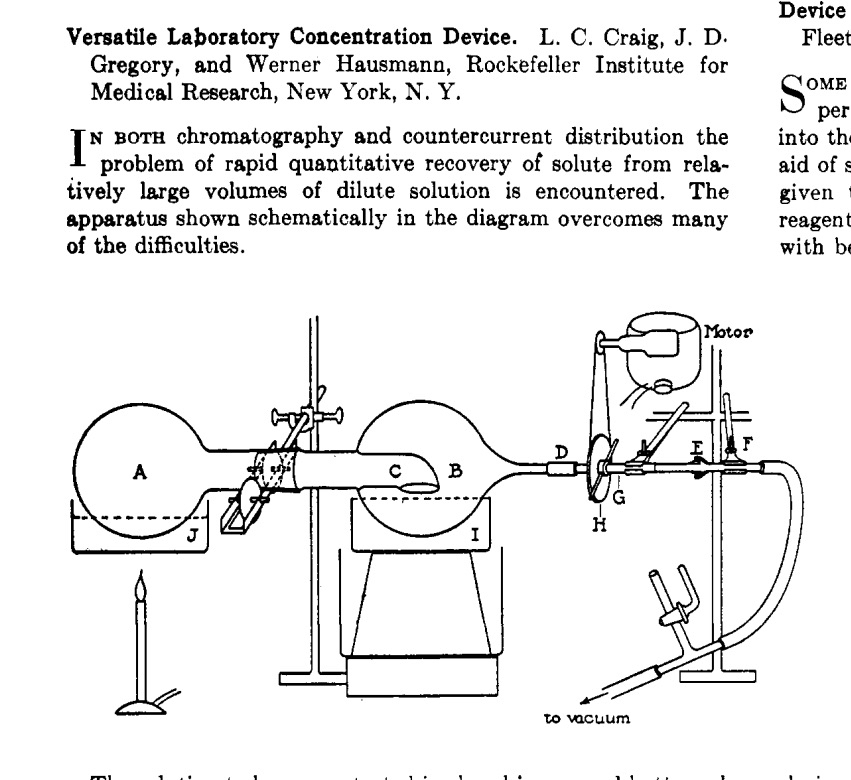

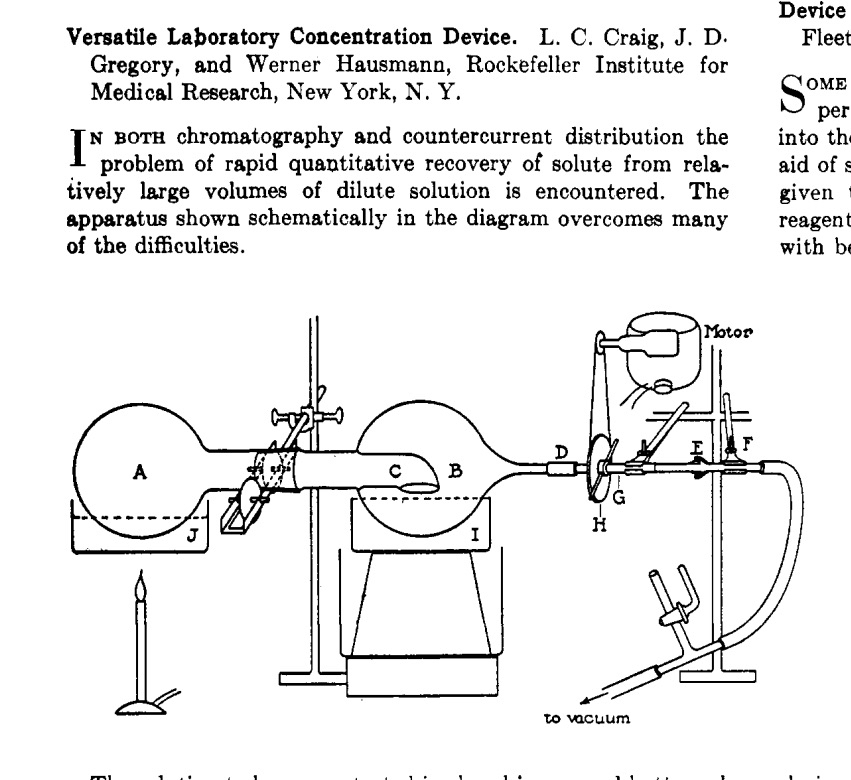

adapt any roller ball mill to a rotovap with only a water bath, courtesy of the 1950s' chemists:

you can literally just place a flask on a ball mill, small enough to be heated from the underside via water bath, then connect it with a ptfe stirrer bearing to a chromatography bulb connected to vacuum

an alternative setup, and show-off of fancy dimroth condenser :D

Mechanical projects

09/03/2025

i have time again now- this post will be the start of an ongoing "cheap rotovap" arc I guess.

Recently I have gotten access to a friend's very nice out-of-service CNC lathe, and I have been working to get it back in working condition for a few days.

I plan to use this to machine some teflon roundstock into a tube with a ring of gear teeth around it, with one end tapered into a ground glass joint.

The rest of the rotovap should be relatively straightforward once I have this one part, as then all I need to do is build a frame to rotate this tube and a water bath.

If I can get this lathe reliably working, I'll probably be able to make a lot of ground-glass tapered joint to standard NPT pipe thread adapters!! This will be very useful.

Additionally I'm partially working on a fume hood right now after getting a decent blower, big things coming :D

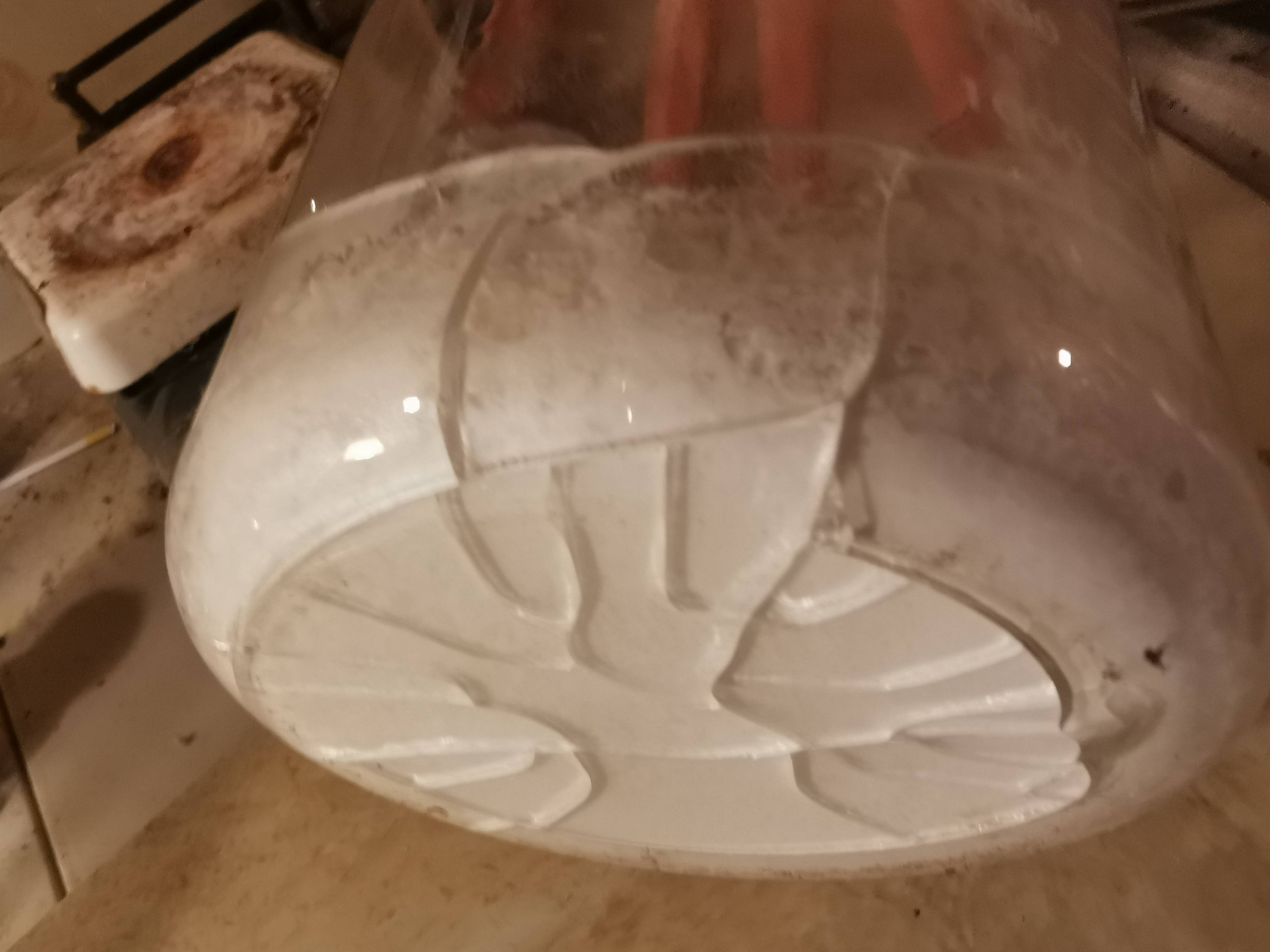

Lost a large beaker, reason unknown.

07/21/2025

Trying to dehydrate potassium phosphate in a 1500ml beaker when it suddenly massively cracked all the way through. Since most of the salt was solid, I did not actually lose any of it, but I don't think I can get it out of the beaker without sending the bottom off. Oh well.

The interesting thing is, the beaker never went above 150C, and is also Corning Pyrex? I'm really doubting the reliability of where I bought these, since I bought a 4-pack. Maybe there was some invisible damage during shipping, which is incredibly worrying for future usage of the other 3 beakers in the box. At this point, I might even try to look through a polarizing filter and anneal the rest at this point if I see any residual stress pattens.

Besides damage during shipping or counterfeit glass, the first possibility which comes to mind was obviously thermal shock. However, I very doubt this. The beaker was never suddenly heated or cooled, and was on a temperature-controlled ceramic hot plate that has served me well for years. But maybe hot spots formed due to some areas of the potassium phosphate fully dehydrating, which would lead to thermal shock?

My other completely speculative guess is due to the phosphate ion. It's well known hot phosphoric acid etches glass, so analogously the large concentration of phosphate ions somehow intercalated into the glass of the beaker at high temperatures, causing uneven expansion in the crystal structure and explosion? Or is it from the potassium ions intercalating the smaller sodium ions, similar to the manufacture of tempered glass? The reason I don't fully believe this is because of the relatively low temperatures in the beaker, and the phosphate still being in an aqueous solution and not molten, and thus very coordinated by water.

So it's a unknown reason. Hopefully, this doesn't happen when I'm working with heavy metal salts in those beakers. Perhaps the overall lesson is to always take precautions of even reliable glassware suddenly exploding.

Cracked beaker

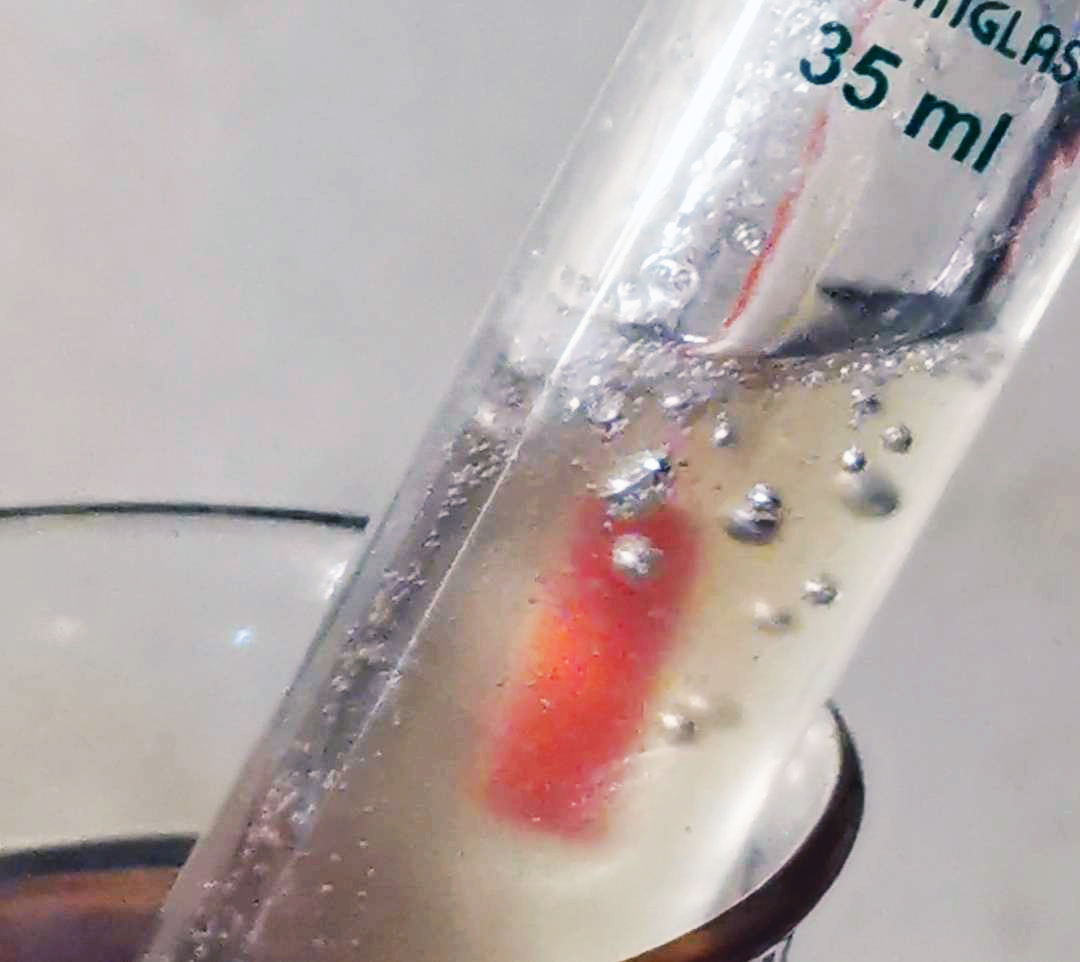

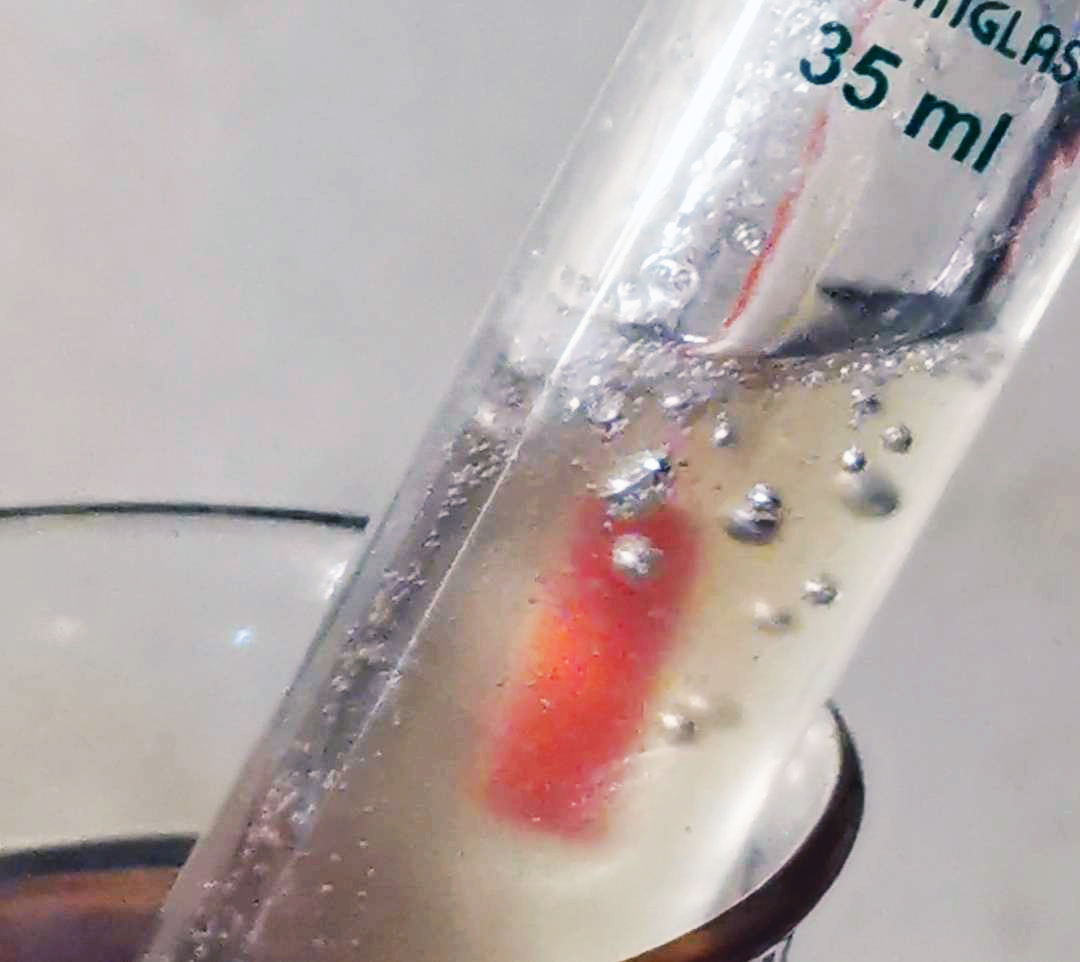

Successful production of sodium!!

07/16/2025

I finally managed to make a small amount of sodium metal! It's only around 2 grams or so, but I can scale this up for future runs decently easily. I'm going to make more and use this to make some alkoxides for a Claisen condensation, planning to synthesize acetylacetone soon to make some nice metal complexes.

Drops of molten sodium in mineral oil

electrolysis-produced sodium failure

07/10/2025

Recently I tried making sodium through adding anhydrous AlCl3 to propylene carbonate, planning to form a very soluble Na[AlCl4]- complex in propylene carbonate which can be electrolyzed to plate out sodium metal. Unfortunately, the first addition of AlCl3 turned the propylene carbonate to brown tar. Chemistry is evil. The propylene carbonate is still a bit wet, I'll put some molsieves in it for a few weeks and see if this works better in the future.